In today’s fast-evolving printing industry, achieving superior aesthetics, precise branding, and mass production capability is no longer optional—it’s essential. Among the many technologies contributing to these demands, the automatic hot stamping machine stands out as a powerhouse. It brings speed, accuracy, and eye-catching metallic finishes to various industries such as packaging, cosmetics, publishing, and more.

One of the most reliable solutions available today is the automatic hot stamping machine offered by leading innovators in the field. These machines combine advanced mechanics with intelligent automation to offer flawless results that are both visually stunning and production-efficient, catering to the evolving needs of modern businesses.

The Basics: What Is an Automatic Hot Stamping Machine?

Hot stamping is a specialized process that involves transferring metallic or pigmented foil onto a surface using heat and pressure. This method is widely recognized for adding a luxurious and professional touch to packaging and printed materials. An automatic hot stamping machine enhances this traditional process by introducing automation into each step—material feeding, stamping, alignment, and collection—resulting in reduced errors, higher output, and consistent quality.

Unlike manual or semi-automatic machines, fully automated systems require minimal operator intervention. This not only boosts productivity but also minimizes labor costs and the potential for human error.

Why Businesses Are Switching to Automation in Foil Stamping

1. Precision Meets Speed

One of the most valuable advantages of an automatic hot stamping machine is its ability to combine high-speed operation with unmatched precision. These machines can handle large volumes of printing within a limited timeframe while delivering the same crisp, clean finish on every item. From metallic logos to holographic security foils, consistency is never compromised.

2. Scalability for Growing Demands

As product lines expand and customer expectations rise, companies need equipment that can scale accordingly. Automation allows manufacturers to increase production capacity without sacrificing quality, making it ideal for businesses aiming to grow without overburdening their workforce or increasing lead times.

3. Enhanced Brand Perception

Hot stamping is often used for luxury products because of the visual impact it creates. A golden logo, embossed title, or holographic seal on packaging can instantly elevate a product’s perceived value. With automatic systems, you can apply these premium finishes consistently across thousands of units, reinforcing your brand’s image on a broader scale.

How the Technology Works

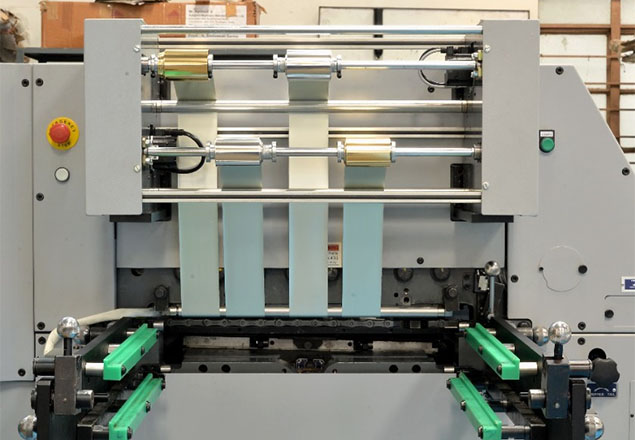

Automatic hot stamping machines are equipped with high-precision servo motors, intelligent temperature control units, and programmable foil feed systems. Here’s a breakdown of the key stages:

- Material Feeding: Sheets or rolls are automatically fed into the machine.

- Registration & Alignment: Optical sensors and alignment software ensure each item is perfectly positioned before stamping.

- Stamping: Heated dies press the foil onto the substrate with just the right amount of pressure and temperature.

- Foil Advancement: Used foil is rolled away while new foil is advanced, all handled automatically.

- Collection: Finished items are neatly stacked or delivered to the next production stage.

This seamless process ensures that every product comes out uniform and defect-free.

Applications Across Diverse Industries

Luxury Packaging

Brands in cosmetics, perfumes, and premium beverages use hot stamping to make their packaging more visually appealing. Foil stamping adds elegance to labels, boxes, and containers.

Book Covers & Stationery

Publishers and designers use hot stamping to create embossed and metallic titles on book covers, wedding invitations, and corporate stationery.

Electronics & Tech

Automatic hot stamping machines are also used for adding brand labels, safety certifications, and decorative finishes on tech products and packaging.

Pharmaceuticals

In a sector where authenticity and trust are paramount, foil stamping is often used for tamper-evident seals and authentication labels.

Key Features to Look for in an Automatic Machine

When considering an investment in such equipment, it’s important to evaluate specific features that align with your production needs:

- Multi-Zone Temperature Control: Enables stamping on various materials like paperboard, plastics, and synthetic surfaces.

- High Tonnage Capability: Essential for embossing thicker or textured materials.

- Touchscreen Control Panel: Offers user-friendly operation and programmable memory settings.

- Quick Die Setup: Reduces downtime during job changes.

- Waste Reduction Systems: Advanced foil management ensures efficient usage and cost savings.

Eco-Friendly and Cost-Effective

Beyond aesthetics and functionality, modern automatic hot stamping machines are designed with sustainability in mind. Many models come with foil-saving modes that minimize waste, and because hot stamping doesn’t require drying time like ink-based systems, it reduces energy consumption and emissions.

Moreover, by reducing labor costs, rework, and material waste, businesses can see a strong return on investment over time.

Challenges and Considerations

While the benefits are numerous, integrating an automatic hot stamping machine does come with considerations:

- Initial Cost: High-end machines can be expensive upfront, but the long-term savings justify the investment.

- Training: Operators must be trained to handle automated settings and maintenance procedures.

- Space Requirements: Some models are large and require sufficient workspace and infrastructure.

However, for companies producing medium to large print volumes, the long-term advantages far outweigh the challenges.

Looking Ahead: What’s Next in Hot Stamping Technology?

The future of hot stamping lies in smarter automation, AI integration, and increased adaptability. Next-gen machines are expected to offer:

- Real-time monitoring via cloud connectivity

- Predictive maintenance alerts

- Improved compatibility with biodegradable foils

- Even more energy-efficient operations

These innovations are transforming hot stamping into not just a finishing process but a vital component of sustainable, high-performance manufacturing.

Final Words

The automatic hot stamping machine represents the convergence of beauty, precision, and efficiency in modern printing. Whether you’re a packaging manufacturer, publishing house, or a cosmetics brand, adopting this technology means more than just upgrading machinery—it’s about committing to quality, consistency, and innovation.

With its blend of aesthetic brilliance and technical excellence, automatic hot stamping is not just a process—it’s a strategic asset in today’s competitive marketplace.