Swiss lathe machines have evolved significantly over the years, incorporating advanced technologies that enhance precision, efficiency, and versatility. These innovations address the demands of modern manufacturing, where complex components, tight tolerances, and high production rates are increasingly common. Understanding these developments can help manufacturers select the right equipment to optimize workflow and quality.

Multi-Axis Capabilities

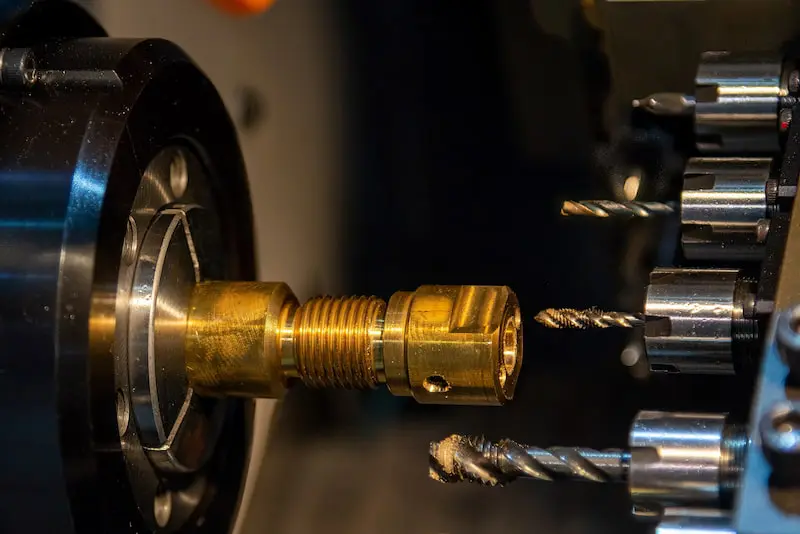

One of the most notable innovations in Swiss lathe machines is the integration of multi-axis functionality. Modern machines can perform simultaneous turning, milling, drilling, and threading in a single setup. This reduces the need for multiple machines or secondary operations, cutting down on cycle times and minimizing handling errors. Multi-axis capability allows for complex geometries to be produced accurately and consistently, improving both productivity and part quality.

Advanced CNC Control

CNC technology has transformed Swiss lathe operations by providing precise control over spindle speed, tool movement, and feed rates. Modern CNC systems feature intuitive interfaces, real-time monitoring, and adaptive tool paths that respond to variations in material or cutting conditions. A high-performance swiss lathe machine utilizes these capabilities to maintain consistent tolerances, reduce human error, and allow for efficient production of intricate components.

Live Tooling and Automation

Live tooling has become a standard feature in many modern Swiss lathes, enabling milling and drilling operations directly on the machine. Coupled with automation tools such as bar feeders, automatic tool changers, and part loaders, this innovation allows for continuous production with minimal operator intervention. Automation not only increases throughput but also reduces the risk of errors and enhances overall workflow efficiency.

Improved Workpiece Support

Modern Swiss lathe machines incorporate enhanced guide bushing systems that stabilize the workpiece close to the cutting tool. This design innovation minimizes vibration and deflection, particularly when machining long or slender components. Improved support ensures better surface finishes, tighter tolerances, and fewer rejected parts, making these machines ideal for high-precision industries such as medical devices, electronics, and aerospace.

Enhanced Monitoring and Feedback Systems

New-generation Swiss lathes are equipped with advanced monitoring systems that track tool wear, spindle load, vibration, and operational status in real-time. These systems provide actionable insights, allowing operators to make adjustments before defects occur. Integrated feedback mechanisms contribute to higher consistency, lower scrap rates, and predictive maintenance, ensuring machines remain reliable and efficient over long production cycles.

Flexible Material Handling

Innovations in material handling have further enhanced the versatility of Swiss lathes. Automated bar feeders, precision chucks, and advanced clamping mechanisms enable machines to work with a wide range of materials and diameters. This flexibility supports high-mix or custom production, allowing manufacturers to switch between materials or part designs with minimal downtime.

Compact and Ergonomic Designs

Modern Swiss lathe machines also emphasize space efficiency and operator ergonomics. Compact designs allow for better workshop layout and integration with other equipment, while improved access to controls and tool areas reduces operator fatigue. Ergonomic considerations ensure that maintenance, setup, and programming tasks can be performed safely and efficiently.

Integration with Industry 4.0

Many contemporary Swiss lathes now include connectivity features that align with Industry 4.0 initiatives. Machines can transmit operational data to centralized systems for monitoring, analytics, and predictive maintenance. This integration supports smarter decision-making, reduces downtime, and enables continuous process improvement across manufacturing facilities.

Conclusion

Innovations in modern Swiss lathe machines have transformed precision manufacturing by enhancing multi-axis capabilities, CNC control, live tooling, automation, workpiece support, monitoring systems, material handling, ergonomics, and connectivity. These advancements improve accuracy, efficiency, and versatility, allowing manufacturers to produce complex components with consistent quality. Adopting modern Swiss lathe technology ensures that production remains competitive, reliable, and capable of meeting the demands of evolving manufacturing standards.