Polyurethane (PU) foam has become an essential material across industries such as automotive, construction, furniture, refrigeration, packaging, and bedding. Its versatility, insulation properties, and durability make it a preferred solution for a wide range of applications. To meet growing industrial demands, manufacturers develop specialized machinery designed to produce different types of PU foam products efficiently and consistently. Understanding the various types of equipment available helps businesses choose systems that align with their production goals.

As the industry evolves, leading PU Foaming Machine Manufacturers continue to expand their equipment portfolios to accommodate diverse applications. From high-pressure systems to continuous production lines, these manufacturers provide advanced solutions tailored to both small-scale and large-scale operations. Selecting the right type of equipment depends on production volume, foam formulation, automation requirements, and end-product specifications.

High-Pressure PU Foaming Machines

High-pressure foaming machines are widely used in industries requiring precise mixing and consistent foam quality. These systems operate by injecting polyurethane components at high pressure into a mixing chamber, ensuring uniform blending and optimal chemical reaction.

High-pressure machines are commonly used in automotive seating, insulation panels, and structural components where consistent density and mechanical strength are critical. They offer superior mixing efficiency, reduced material waste, and improved surface finish. Advanced models often include automated controls, programmable settings, and real-time monitoring features to maintain production accuracy.

Low-Pressure PU Foaming Machines

Low-pressure foaming machines are ideal for smaller production setups or specialized applications. Unlike high-pressure systems, they rely on mechanical stirring for mixing polyurethane components. While they may not deliver the same level of precision as high-pressure equipment, they are cost-effective and suitable for businesses with moderate production requirements.

These machines are frequently used in furniture manufacturing, mattress production, and decorative foam products. Their simpler design makes them easier to maintain and operate, making them a practical choice for companies seeking flexibility and affordability.

Continuous PU Foam Production Lines

For large-scale manufacturing operations, continuous production lines offer unmatched efficiency and output capacity. These systems are designed to produce foam blocks or sheets in a continuous process, allowing manufacturers to meet high-volume demands.

Continuous lines typically include raw material storage tanks, metering systems, mixing heads, conveyor belts, curing tunnels, and cutting units. They are widely used in mattress and insulation industries where consistent block foam production is essential. Automation within these systems ensures uniform density and reduces manual intervention, enhancing productivity and product quality.

Batch Foaming Machines

Batch foaming machines are designed for controlled, small-batch production. They are particularly useful for research facilities, specialty foam products, or manufacturers producing customized formulations.

These machines allow precise measurement of raw materials and controlled reaction conditions, making them suitable for experimental applications or niche markets. Although production capacity is lower compared to continuous systems, batch equipment provides flexibility and control over formulation adjustments.

PU Spray Foam Machines

Spray foam machines are specialized systems used for insulation and coating applications. They mix and spray polyurethane components onto surfaces, creating a seamless insulating layer. These machines are commonly used in construction for roofing, wall insulation, and cold storage facilities.

Spray foam equipment may be portable or truck-mounted, depending on the scale of operations. High-pressure spray systems are preferred for professional construction projects due to their superior mixing quality and application consistency. They provide excellent thermal insulation and air-sealing properties, contributing to energy-efficient buildings.

Elastomer Casting Machines

Elastomer casting machines are designed for producing polyurethane elastomer products such as wheels, rollers, gaskets, and industrial components. These systems ensure precise mixing and controlled pouring into molds.

Elastomer equipment often includes degassing units, heating systems, and precision metering pumps to maintain consistent material properties. Industries such as mining, automotive, and heavy machinery rely on these machines to produce durable and wear-resistant components.

PU Panel Production Equipment

PU sandwich panel production lines are specialized systems used to manufacture insulated panels for construction and refrigeration applications. These lines integrate foaming machines with panel forming and lamination systems.

The equipment ensures accurate foam injection between metal sheets, creating panels with excellent thermal insulation and structural strength. Automation in these systems improves production speed and ensures consistent panel thickness and density.

Foam Cutting and Processing Equipment

In addition to foaming systems, manufacturers also offer foam cutting and processing equipment. These machines are essential for shaping, trimming, and customizing foam products after curing.

Common types include horizontal and vertical cutting machines, CNC contour cutting systems, and peeling machines. Advanced cutting equipment enhances precision, reduces material waste, and supports customized product designs. Such systems are particularly valuable in mattress manufacturing and packaging industries.

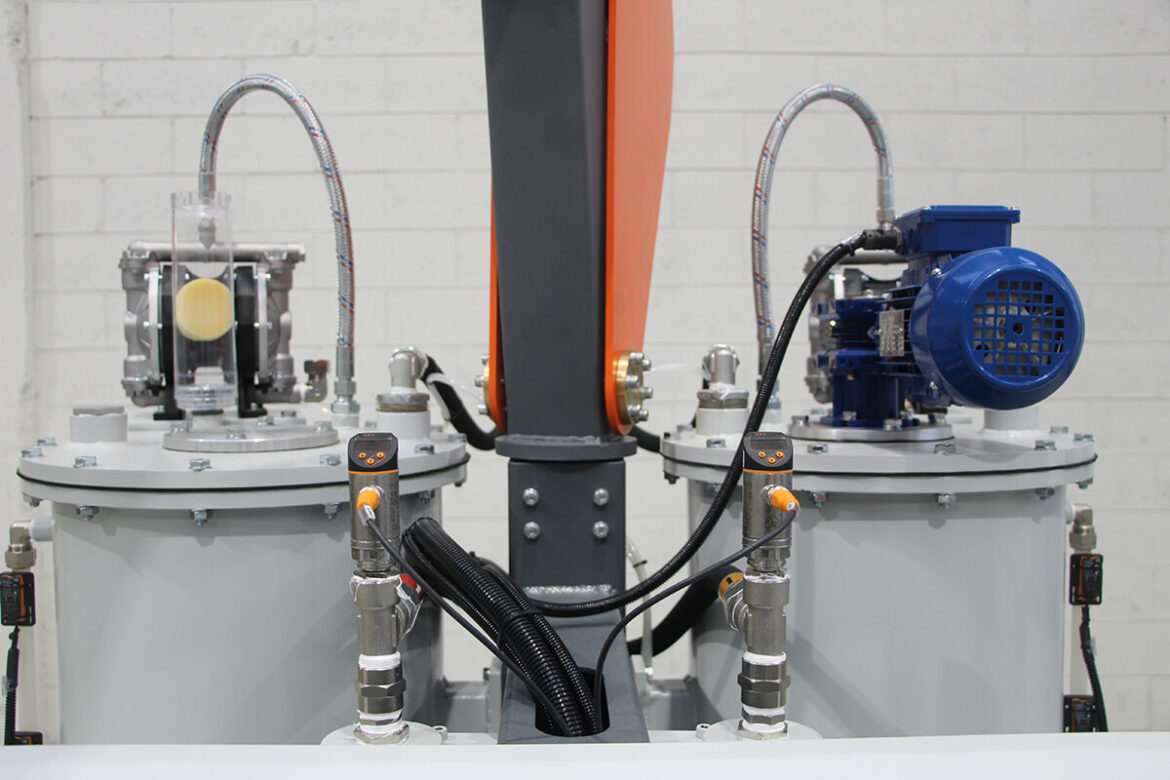

Auxiliary Systems and Support Equipment

PU foam production requires various auxiliary systems to ensure smooth operations. These include raw material storage tanks, temperature control units, mixing tanks, conveyors, and mold carriers.

Auxiliary equipment supports consistent material flow, temperature regulation, and safe handling of chemicals. Integrated systems improve overall production efficiency and maintain stable operating conditions.

Conclusion

PU foaming machine manufacturers offer a wide range of equipment designed to meet diverse industrial requirements. From high-pressure and low-pressure systems to continuous production lines and spray foam machines, each type of equipment serves a specific purpose. Additional solutions such as elastomer casting machines, panel production lines, and cutting systems further expand manufacturing capabilities.

Understanding the different types of equipment available allows businesses to select solutions that align with their production scale, application needs, and long-term growth strategies. By investing in the right machinery, manufacturers can enhance efficiency, maintain consistent product quality, and remain competitive in the evolving polyurethane foam industry.