Swiss lathes are known for their precision, versatility, and efficiency in producing small, intricate components. For businesses looking to invest in such machines, understanding the product range offered by different manufacturers is crucial. The right choice ensures compatibility with production needs, enhances workflow, and maximizes return on investment.

Types of Swiss Lathes

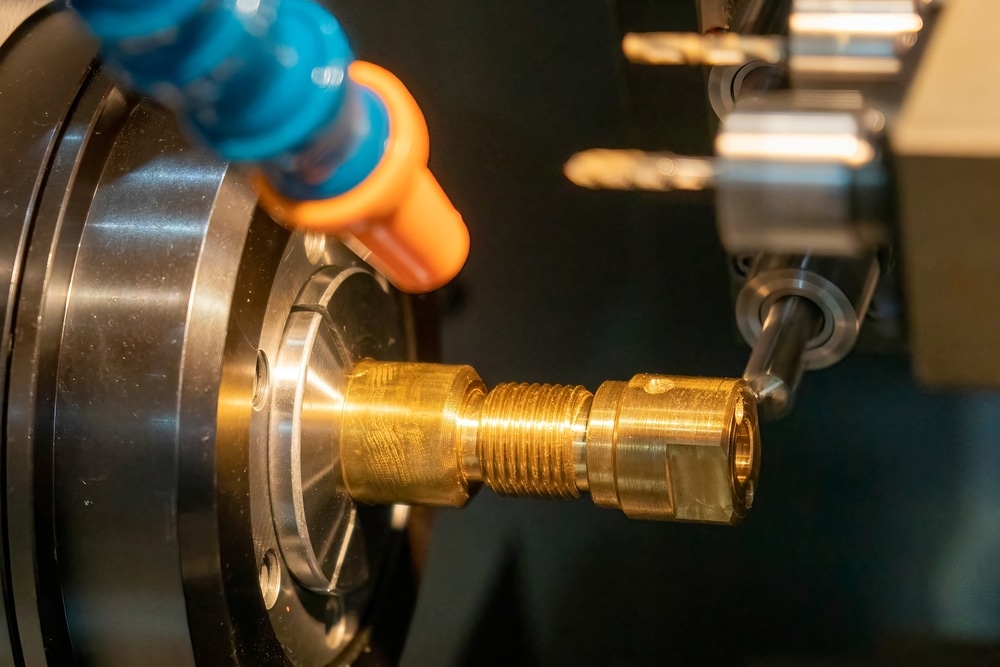

Swiss lathe manufacturers typically offer a variety of machines designed to handle different production demands. Standard models provide essential features for basic turning and threading operations, while advanced models include multi-axis capabilities, sub-spindles, and automated tooling. Choosing the appropriate machine type depends on the complexity of parts, production volume, and specific material requirements.

Assessing Technological Capabilities

A comprehensive product range should reflect the manufacturer’s commitment to modern technology. Features such as CNC integration, high-speed spindles, and intelligent bar feeding systems are now commonly available in contemporary Swiss lathes. A reliable trusted provider of Swiss lathe manufacturers often showcases machines that accommodate both simple and complex operations, offering flexibility to meet varying industrial applications.

Automation and Multi-Function Machines

Many Swiss lathe manufacturers now focus on automation to improve productivity. Machines may include automatic tool changers, robotic part loaders, and synchronized multi-tasking capabilities. These features reduce manual intervention, minimize errors, and allow continuous operation, making them suitable for high-volume or intricate production environments. Manufacturers offering a wide product range ensure that buyers can select models with the appropriate level of automation for their needs.

Customization and Modular Options

An important aspect of the product range is the ability to customize or modularly expand machines. Some manufacturers offer modular turret systems, configurable tool stations, and optional attachments that allow the lathe to adapt to evolving production requirements. Customization ensures that a single machine can serve multiple purposes, improving flexibility and long-term investment value.

Material Compatibility and Size Variations

Different production needs require machines capable of handling a variety of materials, including metals, plastics, and composites. Manufacturers with an extensive product range provide machines suitable for specific material types and diameters, ensuring consistent quality and performance. Additionally, size variations—from compact models for small workshops to larger industrial setups—allow businesses to select machines that fit both space and operational demands.

Software Integration and CNC Control

Modern Swiss lathe manufacturers also focus on software and CNC control integration. Machines in the product range may include programmable cycles, automated error detection, and simulation capabilities. These features reduce setup time, minimize human error, and enhance precision. Manufacturers offering diverse software options allow buyers to choose machines aligned with their technological expertise and production complexity.

After-Sales Support and Training Options

A well-rounded product range often includes complementary services, such as technical support, training, and maintenance solutions. Manufacturers providing comprehensive service packages help operators maximize machine efficiency, ensure proper maintenance, and maintain consistent production quality. These support services become especially valuable for workshops integrating advanced or automated machines into their operations.

Conclusion

Understanding the product range offered by Swiss lathe manufacturers is essential for making a strategic investment. From standard models to fully automated, multi-axis machines, the options available reflect the manufacturer’s technological capabilities, flexibility, and commitment to quality. By evaluating types, automation features, customization options, material compatibility, software integration, and support services, businesses can select a Swiss lathe that aligns with their production needs and long-term growth objectives, ensuring precision, efficiency, and reliability.